Regasification

Natural Gas

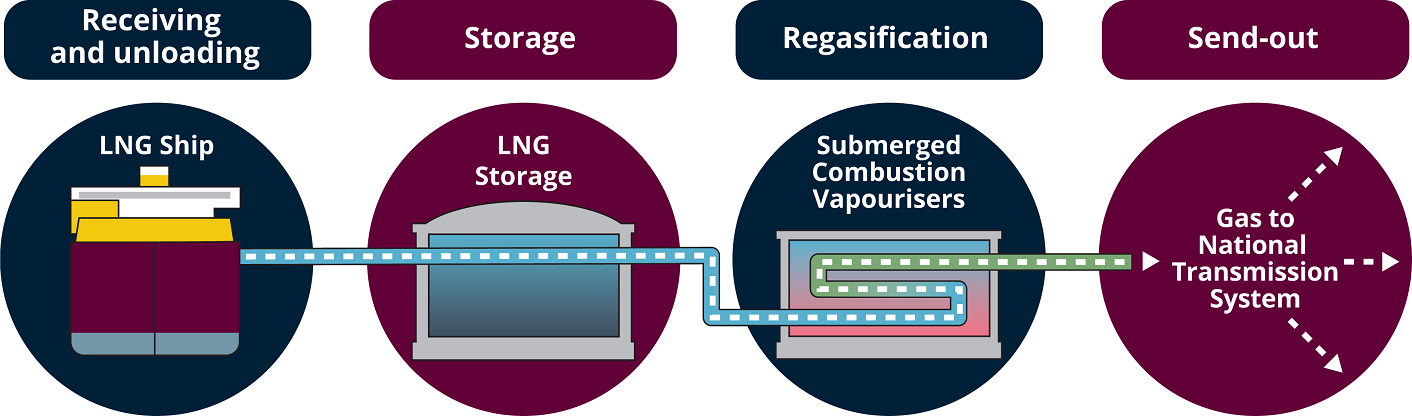

The LNG is converted back to natural gas through a process known as regasification. When natural gas is needed the LNG is passed through Submerged Combustion Vaporisers. Each Vaporiser includes a bundle of tubes housed in a bath of tepid water where the LNG is gently warmed to a point where it reverts to its gaseous state.

The natural gas is then fed into the National Transmission System (a network of gas pipelines which run throughout the UK). South Hook LNG Terminal has a total processing capacity of 15.6 million tonnes per annum, which is equivalent to around 20% of the current UK natural gas demand.